- Home

- Deck Boards

- THERMOASH decking

THERMOASH decking

A warm and very durable board - Sold Out

- Warm colour, marked veins

- Durability - Class 1

- Very Stable - hydrophobic wood

- Knotless

- Low thermal conductivity

A fragrant board with warm colours

Thermo ash decking boards are manufactured using the Thermowood process.

With its knot-free quality and golden colours, this board looks like an exotic wood. A resistant material with low heat conductivity, it is suitable for use in climates with high levels of sunlight.

The grain of the wood and the veins are remarkable and give it all of its beauty. The quarter sawn cuttings give this wood all of its character.

Our ash trees come from North America (USA-Canada). They are then thermo-heated according to the Thermowood process. The surface condition and finish are remarkable.

Smooth on one side with grooved edges to allow invisible fastening with a stainless-steel screw.

Properties of Thermo ash boards are exceptional compared to natural wood or even Ipe boards. Their stability is incomparable to any natural wood species.

- Smooth: 22x130 mm

Characteristics

Felixwood Thermal Treatment

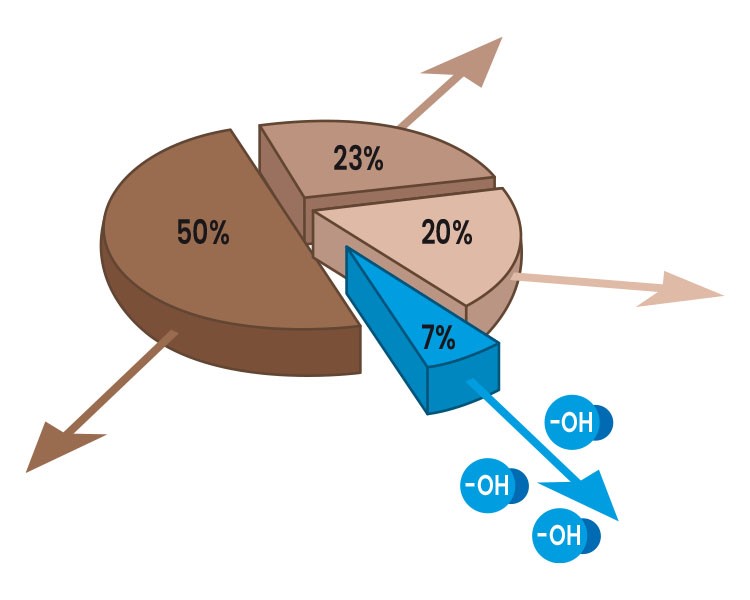

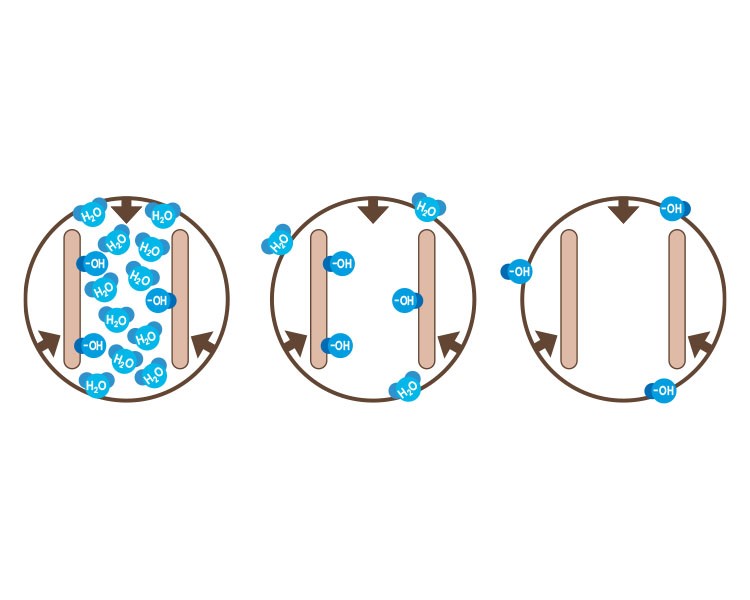

Ash wood is composed of cellulose, hemicellulose, lignin, and other substances such as water. In its natural state, it absorbs moisture from the air as it expands and, in dry weather conditions, it deforms itself in the opposite direction as it shrinks.

Thus, the wood in its natural state is not stable. This is what distinguishes it from other materials.

Properties of the wood can be changed through heat treatment. It becomes hydrophobic, i.e. insensitive to water. Its stability remarkably improves as the sugars have disappeared. It also gains in durability, as fungi and insects with wood-boring larvae are no longer interested in it.

Thermal treatment: a 3-step process

The cycle lasts for 96 hours and is divided into three stages:

Step 1: Drying: the free water (H2O) contained in the wood is evaporated by a regular and moderate rise in temperature up to 140°C.

Step 2: the heat treatment: The temperature rises between 150°C and 210°C for more than 6 hours. Water, or more precisely the hydroxyl -OH groups are extracted from the cell wall. The heat treatment process is carried out at a minimum temperature of 180°C.

Stage 3: the cooling phase: the last stage. The wood is gradually cooled down and stabilised with water vapour to room temperature for about 18 hours.

An ecological process

Thermo-heated wood is chemical free. It is naturally rot-proof without any preservatives. Heat-treated wood from FelixWood is therefore not harmful to the environment nor health. It comes from renewable forests and is recyclable and sustainable.

This wood is also 30% more resistant to fire than ordinary wood.

Thanks to its low water absorption, Thermofrêne maintains its durability in all weather conditions. It lasts longer than ordinary wood. A low moisture content also prevents rot and fungi growth.

Felixwood deck configurator

Make your own quote using our FelixWood mydeckplanner.com configurator.

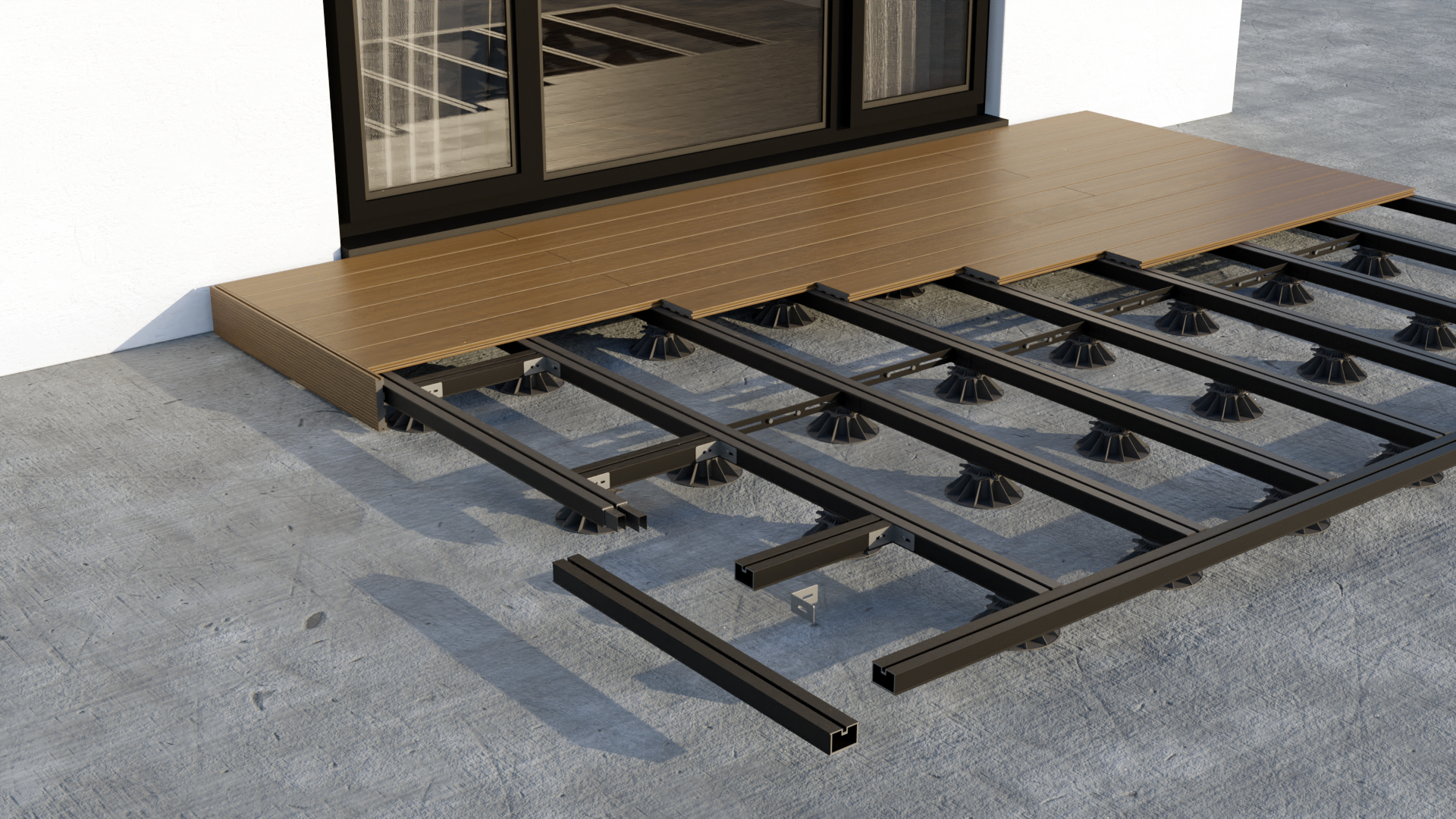

Choose a wood decking board and a type of structure according to your floor and the desired durability of your work: exotic wood joist, aluminium joist, single joist or cross joist...

Specify the type of installation of the deck boards, English style, to scale...

Draw the plan of your deck by selecting the installation accessories and you will get the list of components and the plan of your structure.

All FelixWood woods comply with the European Union Forest Law Enforcement, Governance and Trade Regulation (EU FLEGT). We scrupulously check the certificates of origin of the forest plots. All stages of production, from tree to shipment of the wood are traced and identified. We ensure continuous audit of all our suppliers in accordance with EU FLEGT. As such, 100% of our timber is of legal origin.

But beyond that, we are significantly increasing the proportion of our FSC-certified wood every year.

Installation of the structure

Plan a centre-to-centre distance of 40 cm between joists.

Protect your joists: Use a bituminous strip to cover the joists and prevent water from seeping into the fastening points. The asphalt tape also protects the glued joints of our glued laminated timber joists.

The joists must be laid in such a way as to ensure a 2% slope in the longitudinal direction of the boards to avoid still water on the boards and puddle formation later on.

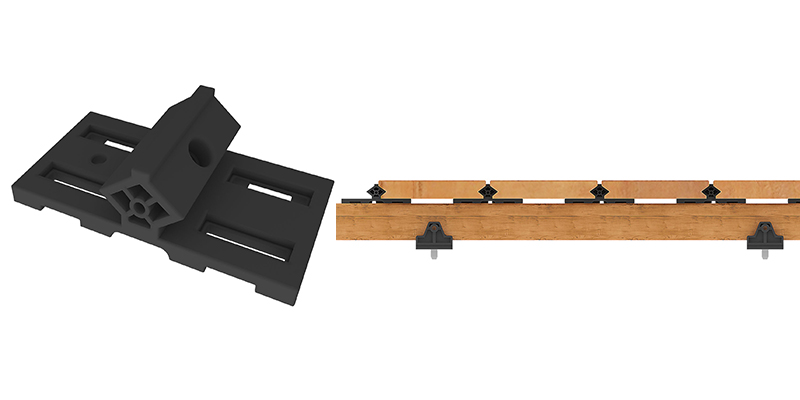

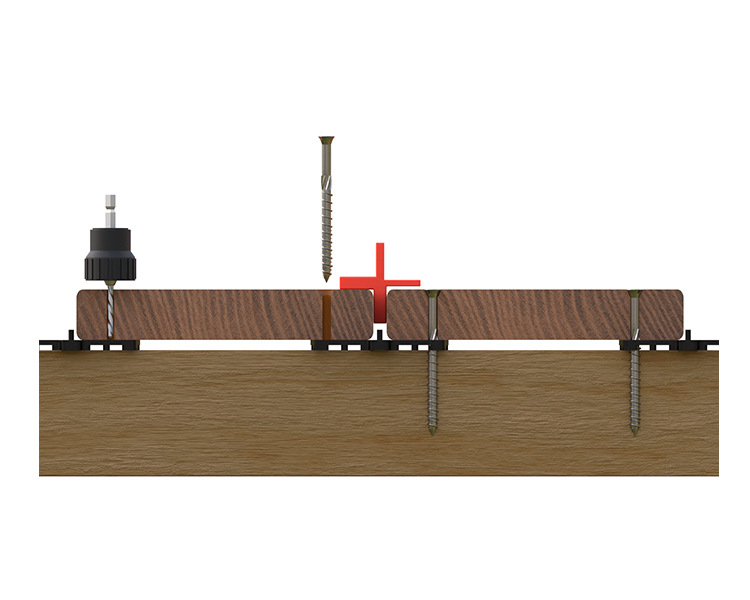

Fixing with clips

The profile of Thermo ash boards allows for installation with a fastening clip fitted with a ventilation shim to allow air to circulate under the boards.

The clip is fastened under the board, and then askew on the clip head with a 4.5x30mm stainless steel screw. Clips are available in boxes of 50pcs with stainless steel screws.

Fastening heat-treated boards by screwing them to the wooden joists.

2 stainless steel screws are required for each fastening point. The

recommended screw diameter depends upon the thickness of the board.

screw diameter = 5 mm

Length of the screw is about 2.5 times the length of the board. The board must be pre-drilled with a drill bit of the same diameter as the screw + countersink. The upper bare side of the countersunk screw must be slightly smaller than the upper side of the board (2mm).

The distance between edges of the board is 1.5 to 2 cm. Use the Cobraliner tool to help you comply with this rule and align your screws.

Always fasten the board edges less than 5 cm from the edge.

Fastening heat-treated boards by screwing them onto aluminium joists.

Two stainless steel screws are required per fixation point. Use metallic self-drilling screws. The board must be pre-drilled with the same drill bit diameter or even slightly larger than the screw diameter + countersink. The upper bare side of the countersunk screw must be slightly smaller than the upper side of the board (2mm).

The distance between the edges of the board is 1.5 to 2 cm. Always fix the ends of the boards less than 5 cm from the edge.

To limit noise pollution and reduce shearing effect on the screws due to aluminium expansion, we recommend applying a 5mm thick Shore 15 EPDM tape to the joists.

Maintenance of heat-treated boards

CAUTION: like most woods, Thermo ash reacts to contact with iron.

The appearance of black spots is the most common reaction. The blue-grey turning black, spike-shaped stains, spreading over larger areas of the wood are wrongly confused with mould.

This is a superficial reaction of the wood with oxidised iron (rust). Damage occurs quickly and suddenly, often at night (from dew or rain).

Remove metal shavings beforehand, avoid contact with lawn fertiliser and cement / plaster. If this has happened, see the information sheet on iron oxide / oxalic acid reaction.