- Home

- Deck Boards

- ROBINIA decking

ROBINIA decking

Europe's most sustainable timber

- 2 smooth sides

- Straight grain, no cross grain

- Coarse grain with visible mesh

- Light yellow colour

- Very durable

- Screw-on

Naturally rot-proof wood with a rustic appearance

Robinia or "fake-acacia", is known for its outdoor uses. It is the most durable of European woods without using any preservatives. It is always the first choice when it comes to avoiding tropical woods.

Like Chestnut and Oak it has a straight grain and a warm yellow to greenish-yellow tinge, but it is much more durable. The heartwood quickly takes on a golden brown tint, then takes on a patina with silver-grey reflections as it ages.

Very durable, it is commonly used for outdoor works, particularly for vine stakes and, more recently, for deck boards.

Originally from the Appalachians, on the east coast of the United States, Robinia was introduced in Europe in the 17th century by Jean Robin, botanist to King Henry IV (France). It developed throughout Europe in temperate climates, at low altitudes and in light, loose soil.

Our Robinia comes from the Hungarian forests, where the grain is straighter. It is in abundance over there as it has been widely planted and represents 20% of the forest massif compared to 1% in Germany and France.

Its melliferous flowers produce large quantities of nectar appreciated by bees to produce a clear monofloral honey with a subtle fragrance.

- 22x120 mm

- 2 smooth sides

- Glued-laminated (Glulam)

Characteristics

Installation of the joists

Plan a centre-to-centre distance of 40 and 50cm between joists. This distance is specified for each of our profiles in the attached table.

The joists must be laid with a slope of 2% in the longitudinal direction of the boards to allow rainwater to run off. This 2% slope must be strictly observed!

Water must also be able to flow under the structure. The joists must be supported on rubber pedestals or supports.

Protect your joists and increase their lifespan: Use the Bitudeck bitumen strip to cover the joists and prevent water infiltration at the fastening points.

Double joisted and cross joisted

Double joisting allows for water to flow between board extremities. Distance between board extremities must be between 4 and 6 mm and distance between the end of the boards and the joist must be between 20 and 30 mm.

Cross joisting

For a faster and longer lasting installation, we recommend cross joisting.

A layer of joists is fixed perpendicularly on a first layer of rafters. The flatness of the deck is easier and quicker to adjust, and ventilation is improved.

In the case of loose and poorly stabilised soil, we recommend the use of galvanised steel foundation screws to ensure effective and durable anchoring of your deck.

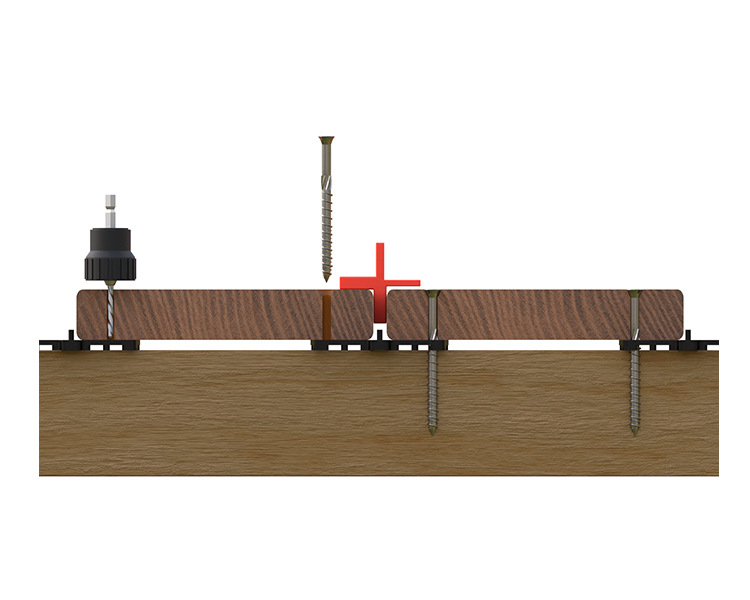

Fixing the boards to the wooden joists

Spacing between the decking boards should be kept between 5 and 7mm (taking into account a wood moisture content of 14-16% at delivery). Use board spacers during installation.

| Humidity of the boards | from 12 to 17% | from 18 to 22% | > 23% at H > PSF |

| Thickness of the spacer shim | 7 or 6 mm | 5 or 4 mm | 3 or 2 mm |

To avoid water being trapped between the boards and the joists, we recommend the use of a ventilation wedge of the Airspacer type. Air circulation under the boards prevents any moisture settling.

Ensure good ventilation of the boards and structure

Never completely close the skirts of the deck to "let the air circulate". Leave a ventilation space of 2 cm between floor and skirting. The minimum space between the decking boards and the ground should be 4 cm to 10 cm for damp floors.

Screw-mounting boards to aluminium joists.

Two stainless steel screws are required per fixation point. Use metallic self drilling screws. The board must be pre-drilled with the same drill bit diameter or even slightly larger than the screw diameter + countersink. The upper bare side of the countersunk screw must be slightly smaller than the upper side of the board (2mm).

The distance between the edges of the board is 1.5 to 2 cm. Always fix the ends of the boards less than 5 cm from the edge.

To limit noise pollution and reduce shearing effect on the screws due to aluminium expansion, we recommend applying a 5mm thick Shore 15 EPDM tape to the joists.

All FelixWood woods comply with the European Union Forest Law Enforcement, Governance and Trade Regulation (EU FLEGT). We scrupulously check the certificates of origin of the forest plots. All stages of production, from tree to shipment of the wood are traced and identified. We ensure continuous audit of all our suppliers in accordance with EU FLEGT. As such, 100% of our timber is of legal origin.

But beyond that, we are significantly increasing the proportion of our FSC-certified wood every year.

Maintenance of ROBINIA boards

Wood turns grey and the surface cracks due to the weather. We recommend oiling the surface, thereby reducing these effects. Only use non water-based non film-forming oils.

Caution: check in advance whether the oil is suitable for the type of wood used. Application of the oil is necessary at least once a year or even several times, depending on location and weather conditions.

After the winter, clean your decking against moss, which represents an increased slippery risk. Never clean with a high-pressure jet.

CAUTION : The appearance of black spots is quite common. These spots, grey or black, spike shaped, are often mistakenly confused with mould. This is a fine metal particles oxidation reaction on the surface of the wood. They can come from a variety of sources (lawn fertilizer, plaster and cement, metal dust from cutting work, etc.). This phenomenon can occur suddenly, after moisture deposit on the deck (dew, rain, etc.).

If this happens, see the information sheet: iron oxide / oxalic acid reaction.

Entretien des lames en ROBINIER

Le bois devient gris et la surface se fissure à cause des intempéries. Nous recommandons d’huiler la surface, ce qui réduit ces effets. N'utilisez que des huiles en phase aqueuse non filmogène.

Attention : se renseigner au préalable si l'huile convient au type de bois utilisé. L’application de l’huile est nécessaire au moins une fois par an, plusieurs fois selon l'emplacement et les conditions météorologiques.

Après l'hiver, nettoyer votre platelage contre les mousses qui représentent un risque accru de glissement. Ne nettoyez jamais avec un jet haute pression.

ATTENTION : L’apparition de taches noires est assez courante. Ces taches, grises ou noires en forme de pointe, sont souvent confondues à tort avec la moisissure. Il s’agit d’une réaction d’oxydation de fines particules métalliques à la surface du bois. Leur provenance peut être multiples (engrais pour gazon, plâtres et ciment, poussières métalliques suite à des travaux de découpe, etc.). Ce phénomène peut se produire soudainement, après un dépôt d’humidité sur la terrasse (rosée, pluie, etc.)

Si cela se produit, voir la fiche d'information : Réaction à l'oxyde de fer / acide oxalique.