- Home

- Wood Cladding

- Thermo Pine ENDURO cladding

Thermo Pine ENDURO cladding

Slats with a trendy combination of false louver

- False louver

- Light - (15% lighter)

- Modular

- Thermowood Scandinavian Pine

- For screwing or nailing

- 100% stable

- No resin

Features

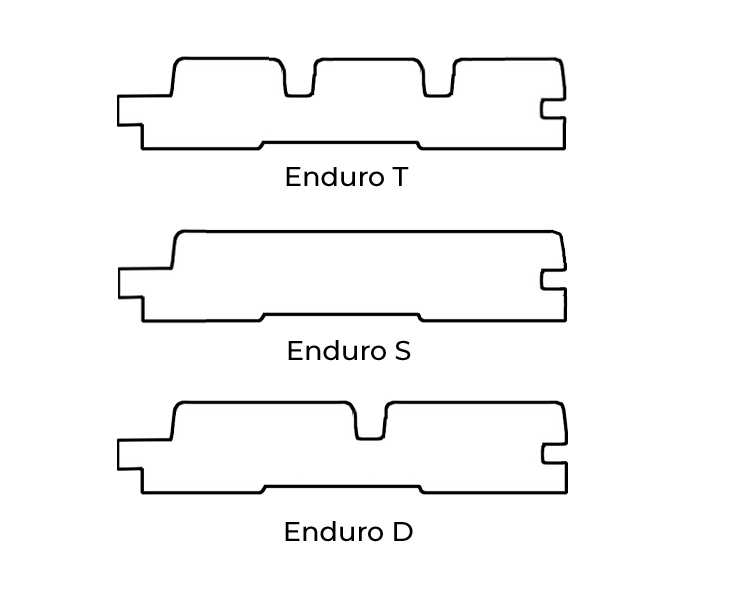

- 3 profiles to choose from: 26x139 mm

- Modular

- Assembly: tongue and groove

Felixwood Thermal Treatment

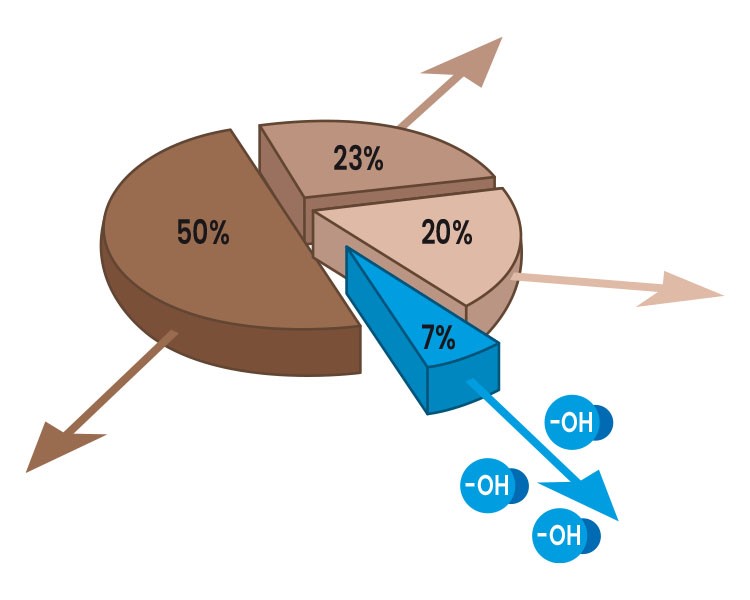

Scots pine consists of approximately 50% cellulose, 23% hemicellulose, 20% lignin and other substances, including water (H2O). In its natural state, the wood is hydrophilic: it absorbs humidity from the air (it expands) and in dry weather it rejects this water and shrinks.

Thus the wood in its natural state is not stable. This is what distinguishes it from other materials.

High temperature treatment changes the properties of the wood. It becomes hydrophobic, i.e. insensitive to water. Its stability improves and it also gains in durability. Indeed, its components: hemicellulose, cellulose and lignin crystallise to become insensitive to the attack of fungi and other wood-boring larvae.

The Thermal Treatment Cycle

The entire process cycle takes 96 hours and is divided into three stages:

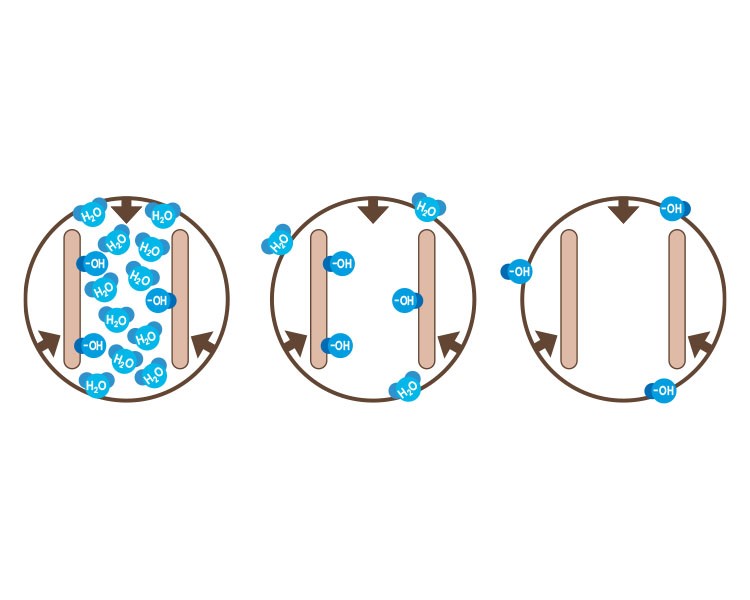

Step 1: Drying: the free water (H2O) contained in the wood is evaporated by a regular and moderate rise in temperature up to 140°C.

Step 2: the heat treatment: The temperature rises between 150°C and 210°C for more than 6 hours. Water, or more precisely the hydroxyl -OH groups are extracted from the cell wall. The heat treatment process is carried out at a minimum temperature of 180°C.

Stage 3: the cooling phase: this is the last stage: the wood is gradually cooled and stabilised with water vapour to room temperature for about 18 hours.

Ecological treatment

Thermo-heated wood is free from chemicals. It is naturally rot-proof without any preservatives. Heat-treated wood from FelixWood is therefore not harmful to the environment nor to health. It comes from renewable, recyclable, and sustainable forests.

This wood is also 30% more fire resistant than ordinary wood.

Thanks to its low water absorption, Thermowood wood lasts longer than ordinary wood. The low moisture content also prevents rot and fungal growth.

ThermoWood® cladding is totally environmentally friendly with a carbon footprint = 3 kg CO2/m2.

ENDURO cladding installation advice

FelixWood ENDURO cladding must be installed in accordance with a few ventilation rules in order to guarantee an optimal and long-lasting appearance.

Respect a minimum air gap of 2cm between the wall and the cladding to ensure optimal high and low ventilation.

Make sure that air can circulate freely at the top and bottom of the cladding.

Leave a space of at least 150mm between the ground and cladding to avoid any rising damp.

Horizontal installation

Attach the laths to the wall in a direction perpendicular to the cladding strips. The cross-section of the cleats must be at least 40mm wide and 30mm thick.

The air gap, an obligatory element, is a free space behind the cladding but before the insulator, which evacuates moisture from possible infiltrations or condensation.

The recommended centre to centre distance is between 40 and 60 cm, which determines the maximum cross-section of the laths that can be used.

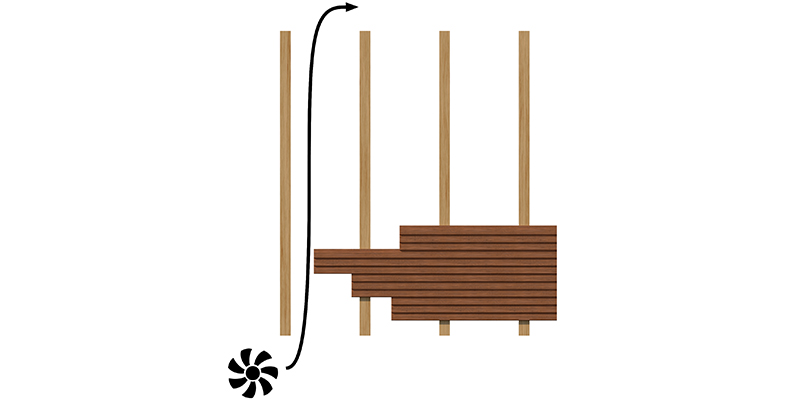

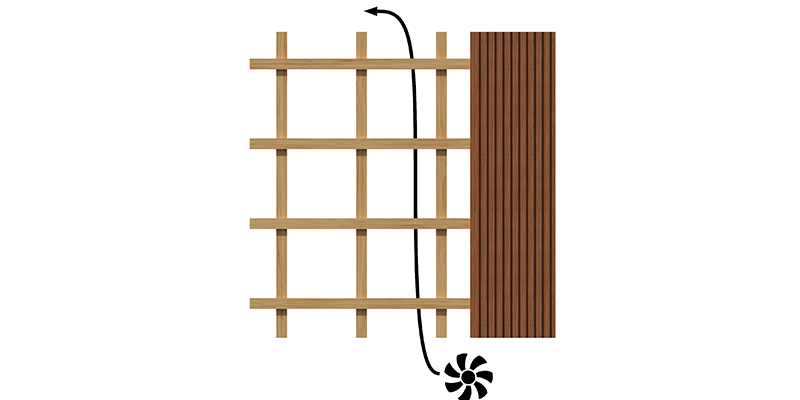

Installation of vertical cladding

In the case of vertical cladding installation, it is important to ensure good air circulation on the underside.

The cleats must be crossed. A first bed of slats is laid vertically, then a second bed is laid horizontally.

The distance between the slats must be between 40 and 60 mm.

All FelixWood woods comply with the European Union Forest Law Enforcement, Governance and Trade Regulation (EU FLEGT). We scrupulously check the certificates of origin of the forest plots. All stages of production, from tree to shipment of the wood are traced and identified. We ensure continuous audit of all our suppliers in accordance with EU FLEGT. As such, 100% of our timber is of legal origin.

But beyond that, we are significantly increasing the proportion of our certified wood every year.

All FelixWood woods comply with the European Union Forest Law Enforcement, Governance and Trade Regulation (EU FLEGT). We scrupulously check the certificates of origin of the forest plots. All stages of production, from tree to shipment of the wood are traced and identified. We ensure continuous audit of all our suppliers in accordance with EU FLEGT. As such, 100% of our timber is of legal origin.

But beyond that, we are significantly increasing the proportion of our certified wood every year.