- Home

- Deck Boards

- SAMBA bamboo decking

SAMBA bamboo decking

Sustainable Decking with a Natural Look

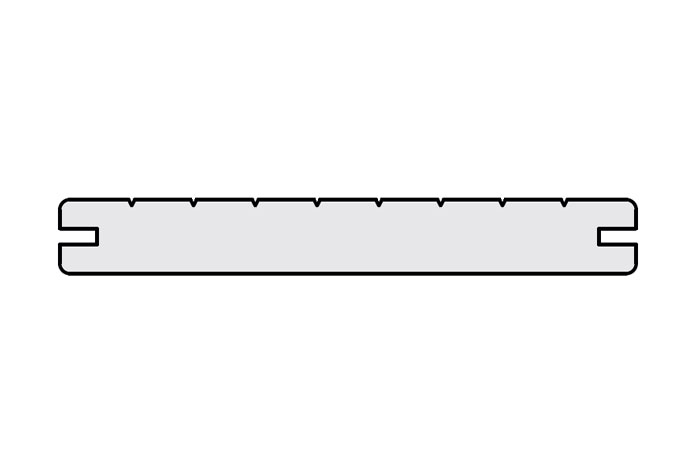

- 1 smooth side - 1 grooved side

- Grooved and interlocking sides

- Fibers bonded together under high pressure

- Particularly hard and stable material

- Installed using Cobra Hybrid 7-22 clips

An Innovation Material for a Natural Deck

The FelixWood SAMBA decking is made of thermally modified bamboo. Bamboo strands are shredded into fibers and then thermally modified at a high temperature. This treatment modifies the sugars present in the plant making the fibers insensitive to attack by insects and fungi. The thermal treatment takes place at a temperature of 150°C and gives the fibers a honey-coloured hue.

The exclusive and patented treatment of our SAMBA decking gives the boards a unique color and greatly enhances their durability. Offered with an oiled finish (water-based), SAMBA boards are installed using invisible Cobra® Hybrid 7-22 clips.

Due to the increasing pressure on (tropical) forest resources, it is essential to offer alternatives to wood for certain applications. FelixWood bamboo is an excellent alternative to tropical hardwood.

- 18x139mm - L 2250 mm

- 1 smooth side - 1 grooved side

Characteristics

NF EN 1534-2010

ISO 4892-3

EN 317 : 1993

(24h in water, at 20°C)

EN 717-1 : 2004

CEN / TS 15083-1 EN

EN 350

EN ISO 178-2019

CEN / TS 15676 : 2007

Bamboo : A Fast Growing Plant

Bamboo is a very fast growing plant that is naturally sustainable. Some shoots can grow several tens of centimeters per day. In general, the plant matures in less than 5 years. When cut, the bamboo root (rhizome) immediately starts to produce new shoots, regenerating the plantation.

The high temperature treatment that FelixWood’s bamboo goes through makes it stable and durable for versatile applications, such as decking and cladding.

FelixWood’s bamboo offers durability and quality that is comparable to the very best tropical hardwood.

Attachment Using Cobra Hybrid® 7-22 Clips

FelixWood SAMBA boards are attached using Cobra® Hybrid 7-22 clips.

Installation is quick and easy: the asymmetric clip fits into the lateral grooves. One side of the clip has 3 teeth, which creates a very strong hold in the groove. The other side is smooth making it easier to connect the next decking board.

The screw is already recessed into the clip and is self-drilling in hardwood (max 850kg/m3) and aluminum. It is not necessary to pre-drill the beam. This saves more than 30% of time compared to a standard clip.

The Cobra Hybrid 7-22 clip can be used in combination with the Cobra® Airspacer ventilation wedges. In addition to guiding the clips, these spacers ensure better air circulation and thus prevent water from standing under the boards.

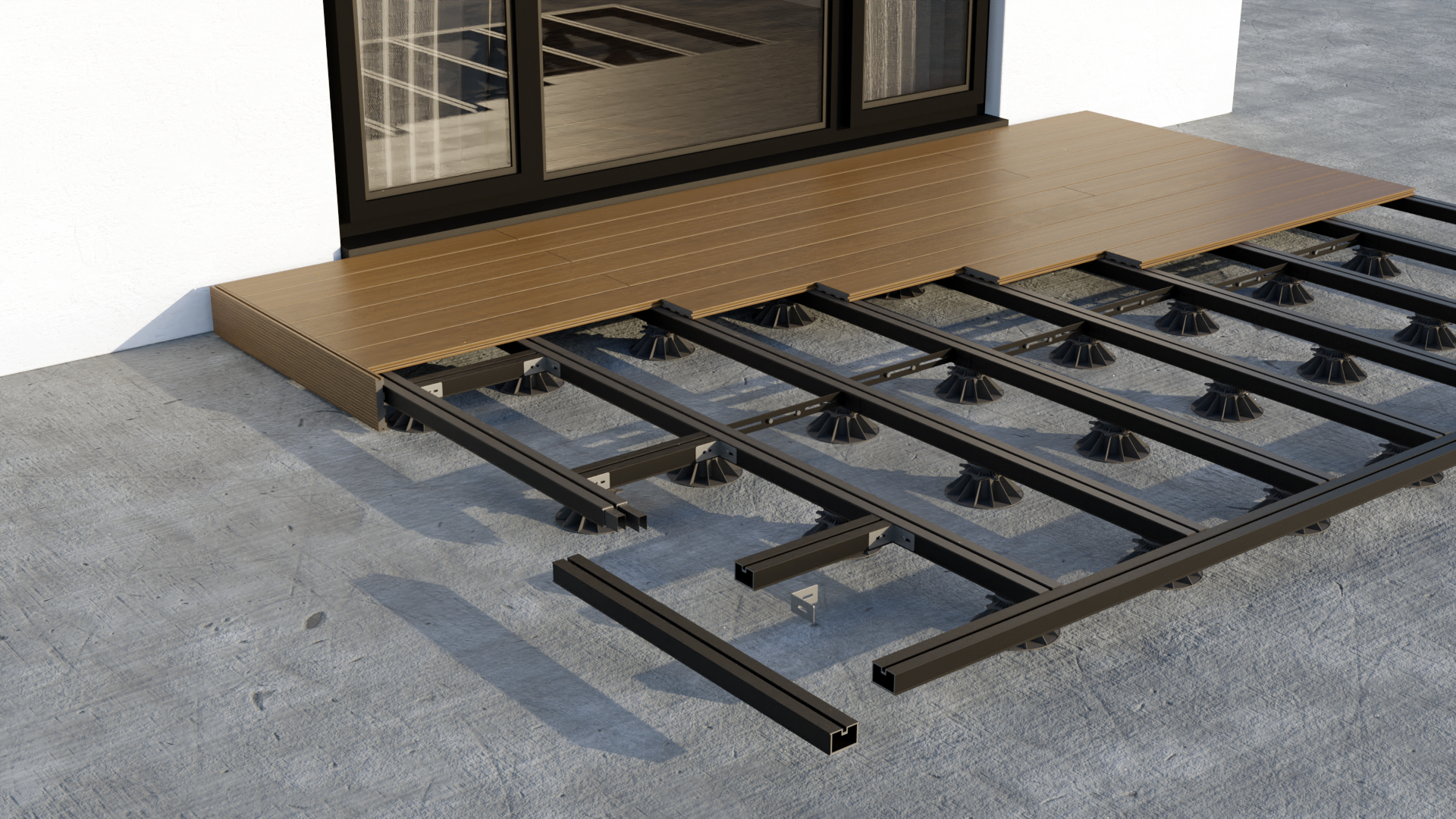

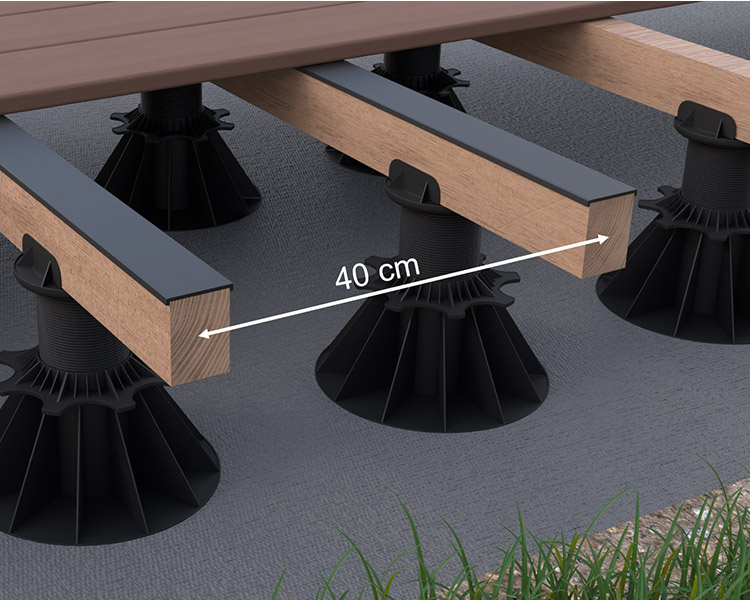

SAMBA Decking Installation

SAMBA thermally modified decking boards are mounted on a wooden or aluminum substructure. It is very important to maintain a maximum center distance of 40 cm between the joists. For areas with intensive traffic (commercial use), a maximum spacing of 35 cm between the joists is recommended.

The joists must be laid with a slope of 2% in the longitudinal direction of the boards to prevent the accumulation of rainwater.

To ensure proper air circulation under the deck, a ventilation space of at least 10 cm must be left between the ground and the decking.

For a neat deck finish, skirting boards can be cut from the decking by sawing off the lateral tongue and groove.

Please note, because bamboo has a particularly high density and is extremely hard, it is necessary to work with very sharp tools.

Bamboo is a fast growing plant. It is an almost inexhaustible resource because it regenerates so quickly. Under normal circumstances, 25% of the bamboo canes can be harvested annually without the plantation shrinking. Bamboo grows back quickly because the roots do not die after harvest. Harvesting the mature bamboo canes increases the yield of the plantation and improves the quality of the bamboo.

No clear-cutting takes place in the plantations. In addition, carbon dioxide is stored in the manufactured cladding and decking for decades! Approximately 1300 kg of CO2 is stored in 1 m3 of thermally modified bamboo.